Power transmission products is a product line that provides sprockets and chains. Required in virtually every industry, power transmission components enable processes to run by connecting moving parts in machinery. The KFB precision steel roller chain is a highly efficient and versatile means of transmitting mechanical power, which, in the field of industrial and agricultural applications, has almost completely superseded all other types of chains previously used.

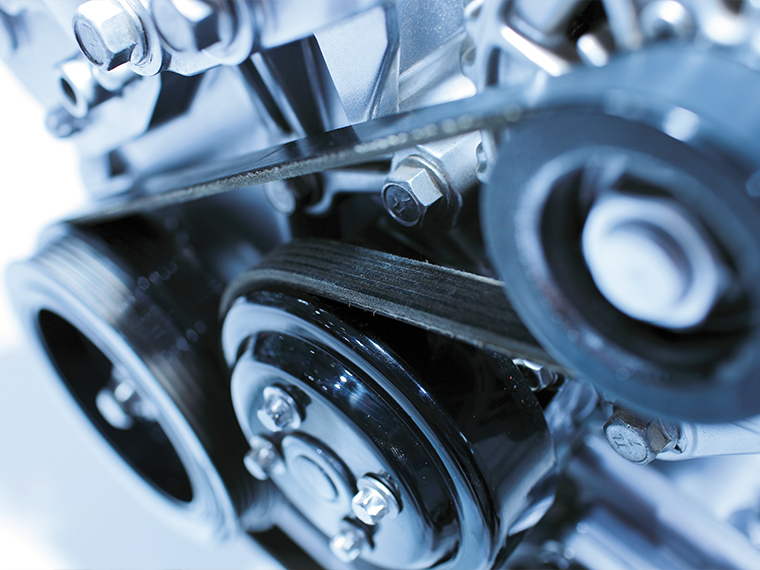

BackKFB Clarfeld Germany specialises in supplying automotive bearings with high quality and related parts to OE specification. We offer a wide range covering all popular bearings in order to support components for the majority of vehicles on the road today.

[table id=3 /]

tensioner bearings

[table id=4 /]

BackDirt, moisture, abrasion and high mechanical loads: driving elements in agricultural machinery and the associated mounted implements are subject to severe strain. The bearings used also have to be tailored to these conditions. It is possible to increase the drive systems’ useful life by selecting the ideal bearings or using customised engineering. Special attention should be paid to the materials and seals.

From the tractor – the universal workhorse – to combine harvesters, field choppers, beet harvesters and the many mounted implements for jobs such as ploughing, harvesting and fertilising, the drive systems for mobile agricultural engineering machines use bearings. These bearings have to operate in more extreme conditions than those used for many other applications.

John Deere

[table id=5 /]

Massey Ferguson

[table id=6 /]

New Holland

[table id=7 /]

Valtra

[table id=8 /]

Backrequire high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant.

The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings.

The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used that are designed for service under severe conditions and in aggressive media (with substantial loads and high temperatures). Thus it is possible to design elements for the supports of roller conveyors (groups of support rollers) used on continous casters.

BackIn the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings.

DEEP GROOVE BALL BEARINGS

The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life.

SPHERICAL ROLLER BEARINGS

In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains and operating conditions of any industry. Heavy loads, debris, severe misalignment and wide variances in speeds are some of the challenges faced by bearings in the excavating, loading, hauling and processing equipment.

• double row cylindrical roller bearings

• ball bearings

• spherical roller bearings

• cylindrical roller bearings specified by UIC

• double row cylindrical roller bearings standardized by UIC

• single and double row tapered roller bearings standardized by UIC

• axle box

• transmission

• traction motors

• B-asymmetrical rollers

• C-symmetrical rollers

• R-bearings without inner rings

• M-machined brass cage, roller centered

• MA-machined brass cage, outer ring centered

• TN-injection moulded cage of glass fibre

• according with ISO 281:2007

• W33-annular groove and three lubrication holes

• P6-according with ISO tolerance class 6

• No code-standard

• C3-greater than standard

• C4-greater than C3

• K-tapered bore ratio 1:12

• No code-cylindrical

Bearings in these applications are subjected to very severe operating conditions. The shaking actions of vibrating equipment subjects the bearings to very heavy loads, including impact loads. Additional load is created by higher “g” forces generated by acceleration in the application. Bearings are higher speed operated. Furthermore, these kinds of bearings are developed to increase the lifetime of bearings in contaminated environments.

KFB designs special spherical roller bearings - MAC4F80 - to operate under severe conditions. Special KFB spherical roller bearings for vibrating equipment are available in 22300 and 23300 series. The clearance is similar to C4, but the lower third of C4 range is eliminated for better control of the bearing clearance after mounting.

Size

[table id=1 /]

Back